Fused Sintered Clamp Sight Glass

sintered clamp sight glass designed for hygienic process monitoring in pharmaceutical, food, and chemical industries.

Compact structure, easy installation, and reliable sealing performance.

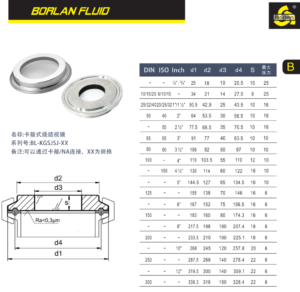

Item No : “BL-KGSJSJ-XX” , ” XX” means SPEC . example: BL-KGSJSJ-1.5, mesns i.5 inch ,TC 50.5mm.

Product Overview

The fused sintered clamp sight glass is designed for visual inspection of fluid flow in hygienic piping systems.

It allows operators to monitor process conditions without disassembly, ensuring safety and efficiency during production.

Fused sight glasses are manufactured using advanced metal-to-glass sealing technology, providing excellent pressure resistance and sealing performance.This series is suitable for high-temperature, high-pressure, and vacuum applications.Commonly used in reactors, pressure vessels, and critical process equipment. Unlike some other sight glasses, our fused sight glasses meet the USP Type 1 standard for pharmaceutical use.Wenzhou borlan fluid has been design and product this kind of stainless steel fused sightgalss for many years, we have lot of experience in stainless steel sightgalss and light.

We are a direct manufacturer, a genuine producer of stainless steel tank components. With over 20 years’ experience in stainless steel fabrication, we operate our own factory, workshops and warehouses. Should you visit China, we warmly invite you to arrange an on-site inspection of our facilities. Alternatively, please add our contact details, and we shall provide you with demonstration videos and photographs or you can just check our social media accounts, we’ll share some our daily factory life from time to time !

Key Features

-

Sintered glass structure for enhanced mechanical strength

-

Clamp connection for quick installation and maintenance

-

Hygienic design suitable for CIP and SIP processes

-

Leak-proof sealing performance

-

Compact design for limited installation space

Technical Specifications

Material

-

Body: Stainless steel 304 / 316L/2205/C22/TA2……

-

Glass: Sintered glass

-

Sealing: Food-grade gasket

Connection Type

-

Clamp connection

-

Available sizes: DN【XXX】

Working Conditions

-

Max working pressure: 【10bar】

-

Max working temperature: 【332 F】

Applications

The sintered clamp sight glass is widely used in:

-

Pharmaceutical processing lines

-

Food and beverage production systems

-

Chemical and fine chemical pipelines

-

Hygienic fluid transfer applications

Installation and Maintenance

The clamp-type structure enables fast installation without special tools.

Regular visual inspection and gasket replacement are recommended to ensure long-term sealing performance.

Why Choose Borlan Fluid

Borlan Fluid specializes in manufacturing hygienic stainless steel components.

With stable quality control and customized capability, we provide reliable sight glass solutions for global industrial customers.

Related Products

If having any qustions ,please contact me through wechat、email、whatsapp、X、facebook、linkedin、tiktok or just quote on line!

If you want complete HANDBOOK/Catalogue/brochure,please contact us !

Borlan Fluid can help you throughout the design, sample, production, pack & supply.Borlan Fluid has its own design team which is able to deliver design services for Stainless Steel Tank Accessories.We will send you sample for the brochure after confirmed details.We can also offer you 3D model of our stock product.

Stock sample can send out within 1 day, custom sample doing time is 5-10 days. 1~100pcs

production time is 7~10 days, 500~1000pcs production time is 10~15 days. 1000~3000pcs

production time is 15~20 days.

a).You send us artwork.

b).You pay 30% deposit, if less than 100pcs, we suggest you pay full amount because production time will be quick (7~10 days).

c).We make a digital print proof sample take picture and video for you confirmation.

d).Start production.

e).Balance Paying before package sending out.

We are a professional manufacturer specializing in stainless steel sight glasses, sight glass lights, and tank accessories.

All products are designed and manufactured in our own factory, allowing us to control quality, lead time, and customization.

We supply a full range of stainless steel tank and pipeline accessories, including:

Sight glasses (union, flanged, pipe, fused, tubular)

Sight glass lights (integrated and separate types)

Explosion-proof sight glass lights

Manways and manholes

Spray balls and cleaning accessories

Sanitary fittings and customized tank accessories

Our standard materials include:

304 stainless steel

316 / 316L stainless steel

Other materials can be provided upon request depending on application requirements.

Yes.

All sight glass lights are CE certified, and comply with relevant CE conformity requirements.

Explosion-proof models can additionally comply with ATEX requirements when specified.

Yes.

We provide explosion-proof sight glass lights suitable for hazardous environments such as chemical, pharmaceutical, and petrochemical industries.

Please inform us of the required explosion-proof standard (e.g. ATEX、EX) when making an inquiry.

Yes.

Custom sizes and non-standard dimensions are available upon request.

We can customize:

Diameter and thickness

Connection types (flanged, clamp, welded, union)

Glass type

Lighting configuration

Available connection types include:

Flanged (DIN / ANSI / customized)

Union

Tri-clamp (sanitary)

Welded

Pipe inline connections

Our products are widely used in:

Chemical processing

Pharmaceutical manufacturing

Food & beverage

Biotechnology

Cosmetics

Environmental and water treatment industries

Yes.

We supply separate sight glass lights designed for external illumination of existing sight glasses.

Integrated and separate configurations are both available.

Depending on the model, we offer:

AC power supply

DC power supply

Battery-powered models

Voltage, wattage, and cable length can be customized.

Yes.

We supply sanitary stainless steel sight glasses and accessories, suitable for hygienic applications in food, beverage, and pharmaceutical industries.

All products undergo:

Material inspection

Dimensional inspection

Functional testing

Certification verification (CE where applicable)

This ensures consistent quality and reliability.

Lead time depends on:

Product type

Quantity

Customization requirements

Standard products usually have shorter lead times, while customized products may require additional production time.

Yes.

We support OEM and customized branding for overseas customers, including product marking and packaging.

You can contact us by:

Website inquiry form

Providing drawings or specifications if customization is required

Our sales team will respond with technical confirmation and quotation.

Request A Quote

To know more about our products and services, please fill out the contact form.

Contact Us

We are committed to producing the best quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

jzxiang1992@gmail.com

Phone

+86-16657273263

+8616657273263

borlanfluid

Address

longwan town, wenzhou city,zhejiang province, China.